More Flexible R&D with External Engineering Service Providers

External engineering service providers can make Research & Development more focused, more efficient and more flexible. One of our clients from the automotive industry also wanted to tap into this potential.

The company

The company is one of the largest German automotive and industrial suppliers, possessing three top-performing, global product brands.

The challenge

Our client was providing its R&D services almost completely with internal resources. There was no clear view of the advantages or disadvantages of involving engineering service providers more intensively. This resulted in the following tasks:

- Convincing employees on all hierarchy levels of the advantages of involving external engineering service providers

- Determining the potential of awarding contracts in selected product units

- Developing a portfolio of external engineering service providers

- Commissioning external engineering service providers for selected pilot projects (RFI process, RFQ process, proposal assessment, selection, contracts, awarding contracts)

- Preparing the necessary procedural and organizational changes to use external engineering service providers strategically and regularly

- Defining a roadmap for rolling out the results throughout the whole organization

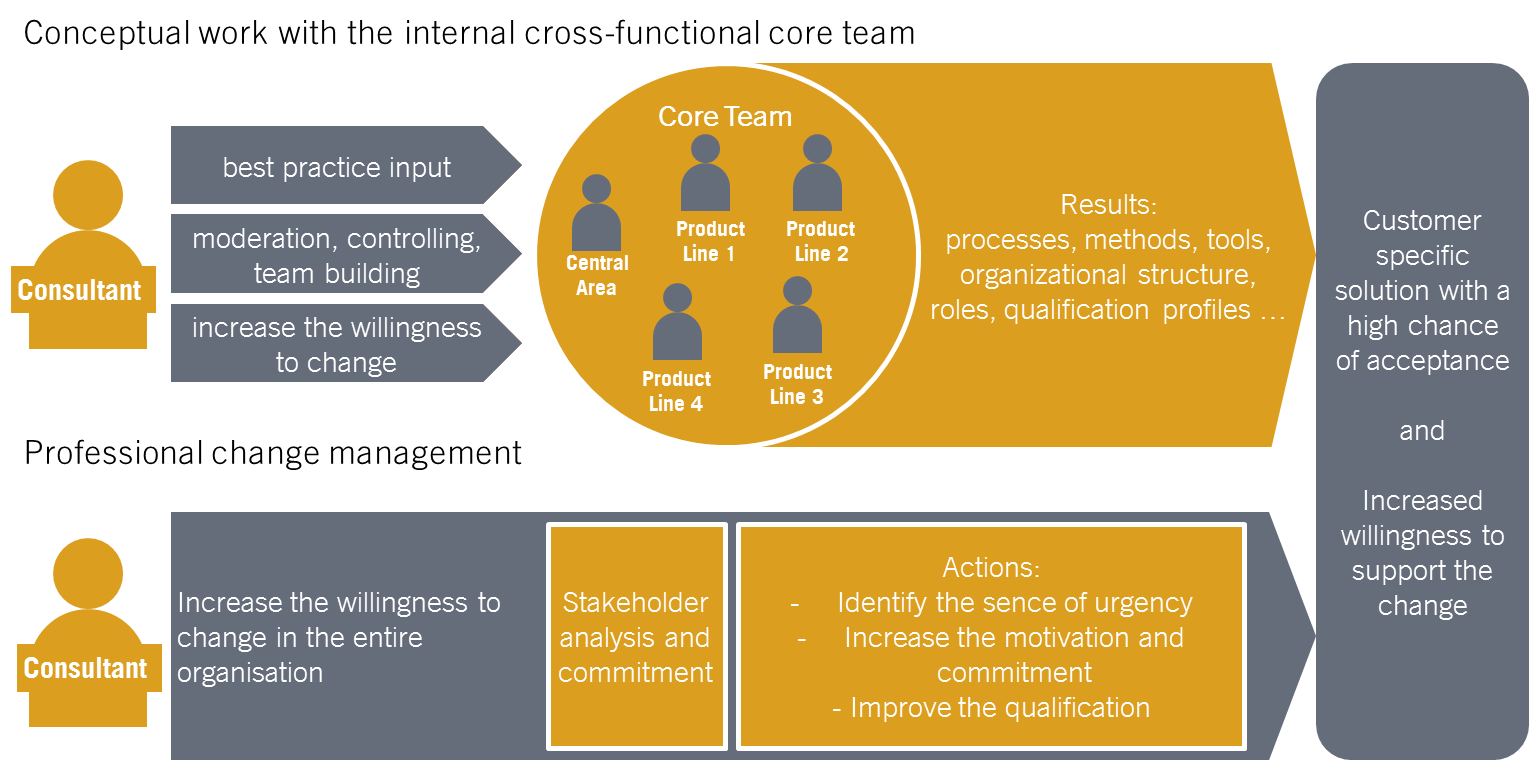

The approach

In each product unit, we applied a uniform approach in eight pilot projects:

- Defining the objectives as well as opportunities and risks involved in cooperating with external engineering service providers – forming a common mindset

- Delineating a matrix of process steps and products/components for the respective unit

- Defining assessment criteria for awarding the contract: achievement of project objectives, exclusion criteria and protection of core competencies

- Systematically determining the potential in the above matrix, identifying the quantity structures

- Quantifying the potential benefits of external engineering service providers for a management decision proposal

- Together with the competent purchasing organization and the legal department: selecting and commissioning the engineering service providers based on the most attractive potential

Furthermore, a process was defined to secure the future use of external R&D, taking into account the needs of all stakeholders. Once the pilot phase was complete, CO-Improve was also involved in the roll-out of the approach to other product units.

“My good people can finally focus on the important stuff and delegate standard tasks. This increases their motivation and my unit’s output.”

Head of R&D Product Unit

Bottom line – the benefits

- High level of acceptance of external engineering service providers as a “regular” partner in project work

- Better results with significantly reduced growth of fixed costs in R&D

- More flexibility and know-how transfer from service provider to client

- Concentration on the unit’s own core competencies

- Control tool for the Management to help achieve a desired ratio of external R&D