Product development process

Product development processes have long been part of the standard repertoire of good R&D management, haven't they? "That's right!", you will say. However, our consulting practice shows that many product development processes no longer meet the new challenges. The increasing product complexity, modularisation, digitalisation, the continuously rising software share and the establishment of agile working methods require a further development of the previous processes. We show you how to do it.

Start with an inventory

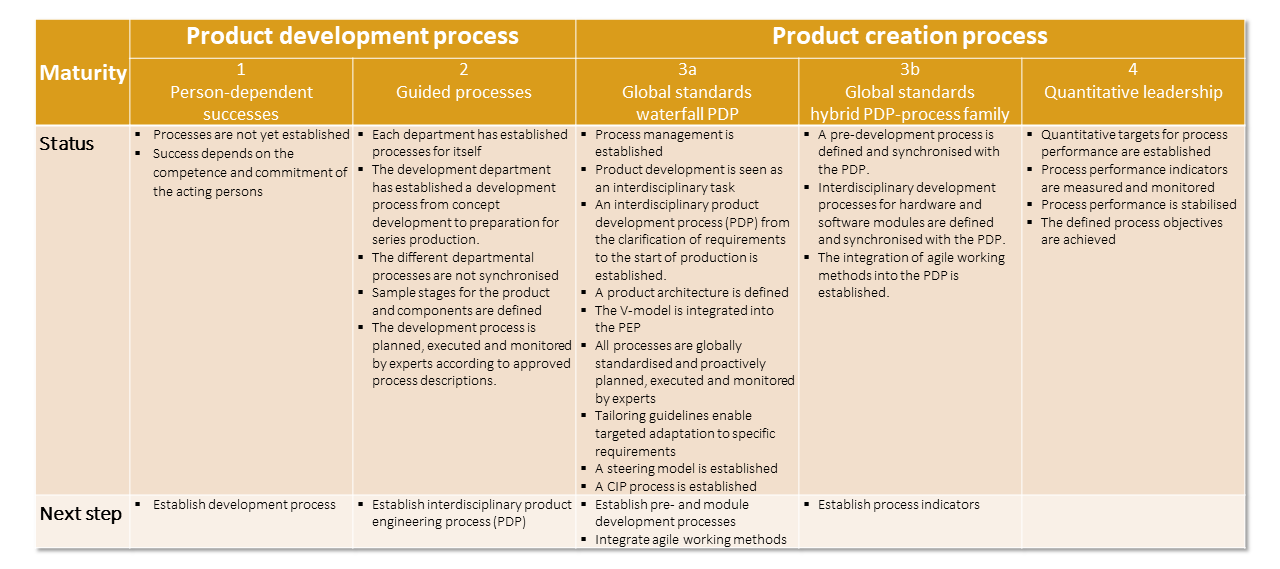

You have already identified potential for improvement in your product creation process. Or you do not yet have a product development process and want to redesign and introduce one. Before you read on, it is helpful to conduct your own systematic assessment. At CO Improve we have been using our own maturity model for many years to determine where we stand in R&D management. This model can also be used for an initial inventory and classification of your product development process.

The PDP describes the interdisciplinary workflow from a product idea through requirements clarification, product development, production, sales and customer service preparation to the successful start of series production. The focus is on balancing the competing goals of high result quality and customer benefit, short time-to-market and low process costs through optimal synchronisation of all areas involved. A revision of the PDP should therefore start with a clear analysis of the initial situation and target definition.

From the product development process to the product creation process.

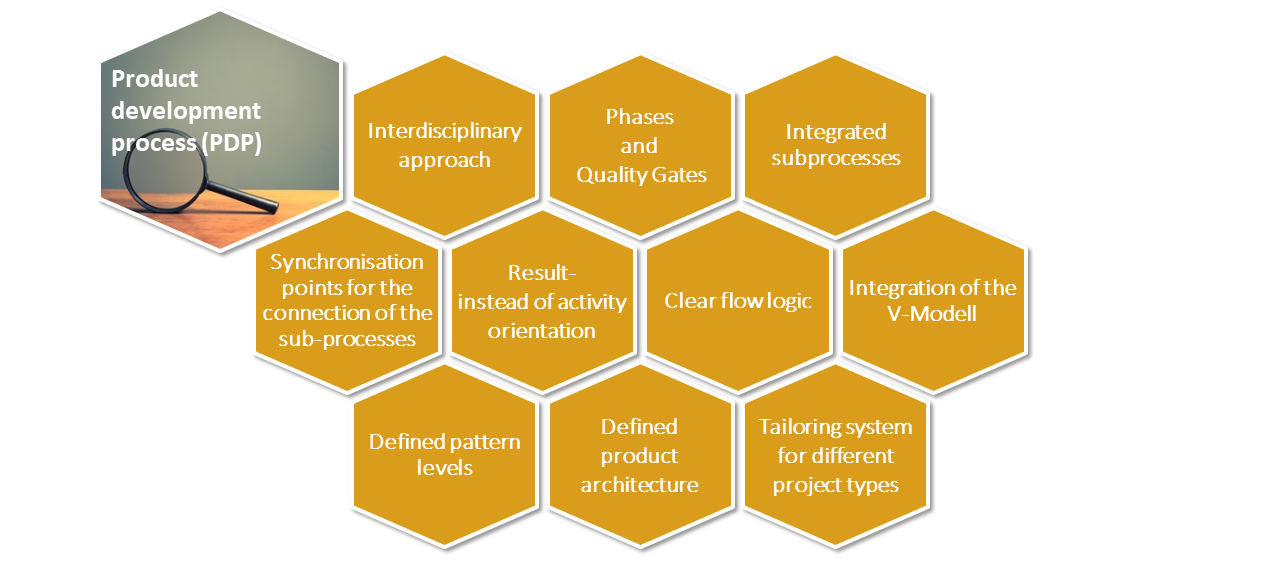

A PDP is only as good as the features that were considered in its design or further development. Many of the design features described below are known, but are better developed today. Other design features are added to adequately meet today's challenges. The process architecture results from the phases and quality gates and the interdisciplinary integrated sub-processes. Synchronisation points and the V-model ensure result orientation and clear process logic. A defined product architecture and defined sample stages are important prerequisites. Tailoring guidelines create a process construction kit for all conceivable project types.

Phases, quality gates and interdisciplinary sub-processes

The primary structuring feature is therefore the phases, each of which is concluded with a quality gate. As a secondary structuring feature, sub-processes are defined that run horizontally in the process representation (swim lanes). In the past, these sub-processes were displayed for the individual departments. Today, interdepartmental interdisciplinary sub-processes are defined. This achieves a higher level of integration and fewer interfaces between the sub-processes. A requirements management sub-process is a good example of this.

The synchronisation points decisively define the process quality

Synchronisation points define all required process results (Deliverables). The advantage over previous activity-oriented process descriptions lies in the result orientation. Synchronisation points should describe exactly which process results, with which acceptance criteria, are to be delivered by whom, which input variables they require and to which other synchronisation points the results are passed on as input variables. A PDP typically has between 80 and 120 such synchronisation points.

This defines a clear flow logic for the process and the exact description of the results leads to a high quality of results right away (Right-First-Time). At the same time, the delivery of required process results can be monitored earlier and does not happen only when the quality gate is reached, as is still often the case. A synchronisation point is always the responsibility of a role in the project core team. To check the quality of the results of a quality gate, all process results of the synchronisation points of the respective phase are brought together in gate checklists.

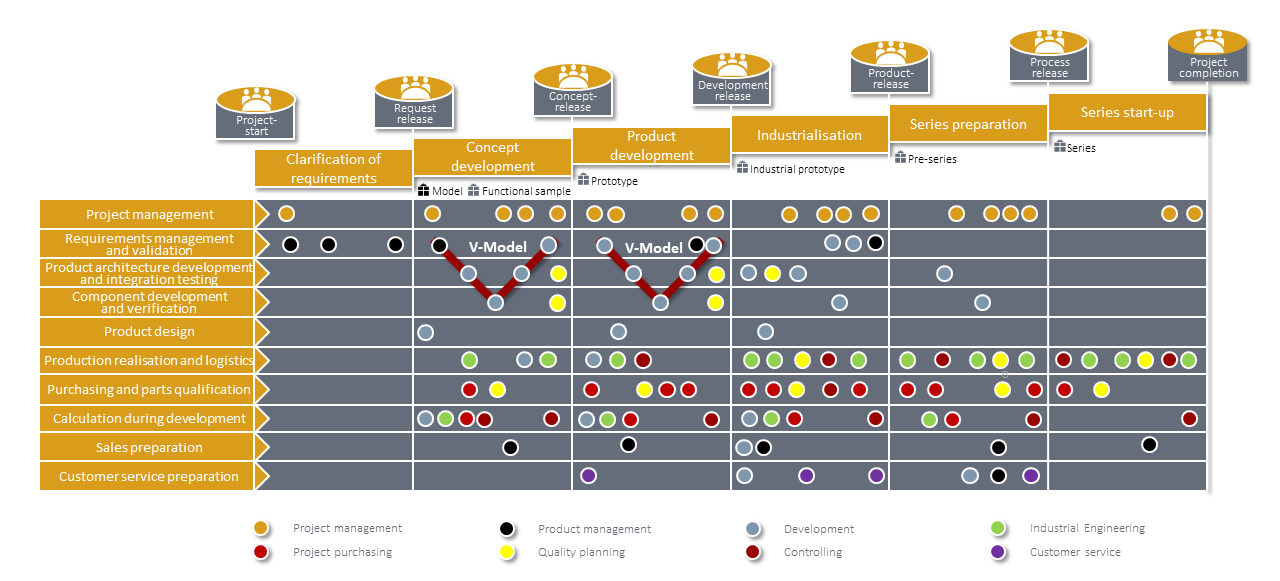

What process representation results from this

The following figure shows an exemplary PEP for an OEM with 7 phases and quality gates, 5 sample stages, 10 interdisciplinary sub-processes, 126 synchronisation points, 8 project core team roles and a V-model run twice. The synchronisation points are linked by predecessor and successor relationships so that a sequence of operations is defined.

PDP tailoring - project-specific process adjustment

To keep your process costs under control, you should provide for the possibility of adapting the PDP to the respective project. This process is also called PDP tailoring. There are various approaches to PDP tailoring.

Control process performance with key figures

Maturity level 4 is characterised by the setting, monitoring and controlling of quantitative process objectives. This means you need another process for process monitoring and optimisation.

And secondly, you need a set of appropriate key performance indicators. These key figures should cover the three target dimensions of process quality (Q), process costs (K) and process times (T). It is advisable not to use too many key figures. The most important key figures are:

-

First pass yield rate or right-first-time rate (Q): The percentage of process results that are accepted on the first attempt at a quality gate review. The key figure can be collected for the entire PDP, for individual phases, for individual sub-processes.

-

Process costs (K): Process costs are usually collected as project costs from project management. Here, too, it is conceivable to record the process costs specifically for individual phases, sub-processes or also cost types, e.g. personnel, material and external costs or also sample costs, verification costs.

-

Time-to-market (T): The time-to-market measures the total lead time for the PDP. It can be recorded as a whole, by phases or even individual process sections, e.g. for prototyping, verification, modifications, etc.

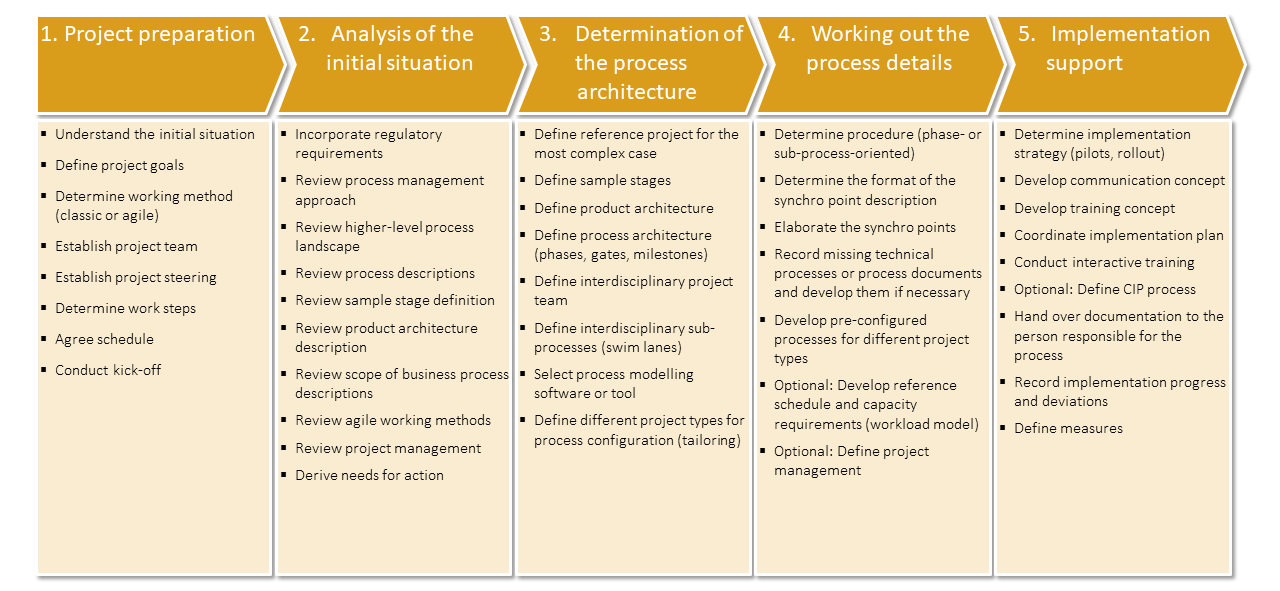

Procedure for redesign or optimisation

Regardless of whether it is the first-time design and introduction or the optimisation of an already established product creation process, we accompany you in 5 steps from project preparation to implementation support.

Conclusion

The product development process is one of the most important performance processes in your company. Increasing product complexity, modularisation, digitalisation or increasing software scopes bring new challenges. This requires a recurring revision of the product development process in order to create competitive products with a high result quality, at acceptable costs and a short time-to-market.

Your benefit

- You benefit from our analysis methodology in determining your current position and deriving your fields of action.

- You optimise interdisciplinary cooperation in your central product development process.

- You define the weighting of the competing goals of high quality results and customer benefits, short time-to-market and low process costs.

- You provide tailoring guidelines for all project types and "don't shoot at sparrows with cannons" for single-axis projects.

- You benefit from our many years of experience and continuous further development of our solution approaches in the design and introduction of product development processes.