Engineering change management

Product creation today is subject to ever-increasing complexity. Markets, products and technologies are just as decisive as the increasing pressure on costs and profitability. Companies often take more risks in the product development process than in the past. One success factor to survive in this challenging environment is professional requirements and engineering change management.

Engineering change management describes functions, processes and tools that are established in an organisation to make changes to products in a controlled and documented manner. There are many possible reasons and triggers for changes: Changed market or customer requirements, functionality or quality that has not yet been achieved, improvement potential for production or customer service, excessive product costs, complaints, volume changes for production, production relocations. Dealing with changes is one of the most important processes in the entire product life cycle.

In the process, engineering change management must meet very different requirements over the product life cycle. In early phases of product development, optimisation loops are deliberately carried out to verify functionality, ensure durability, guarantee quality, ensure readiness for series production and achieve the profit target. At the same time, it is important to keep product costs under control. In the process, many changes are introduced in parallel and at short intervals. Therefore, it is important to introduce and implement changes in a controlled manner, but at the same time quickly, flexibly and efficiently. The closer it gets to the start of series production, the more costly changes become. When it comes to technical changes in series production, the focus is more on aspects such as compliance, i.e. the fulfilment of rules and regulations, functionality or quality that has not yet been achieved, improvement potential for production or customer service, excessive product costs, complaints, supplier changes, volume changes for production or production relocations. In this context, the delimitation of parts in production - old status / changed status - and a controlled incoming and outgoing goods management incl. coordination with the customer are of particular importance.

The essential key in engineering change management is transparency. Due to their significant influence on quality, costs and delivery dates, technical changes must be systematically planned, evaluated and tracked. As a rule, changes affect all areas involved in simultaneous engineering. In view of the large number of procedures, technical processes, departments and affected parts and components, transparent processes are essential. In the data world, it must be easy to see which CAD models are affected by changes, with which change statuses intended tests were carried out, which development status was the basis of the last design review, on which data the current tool design is based and whether the new test results of the prototype already take the last change note into account.

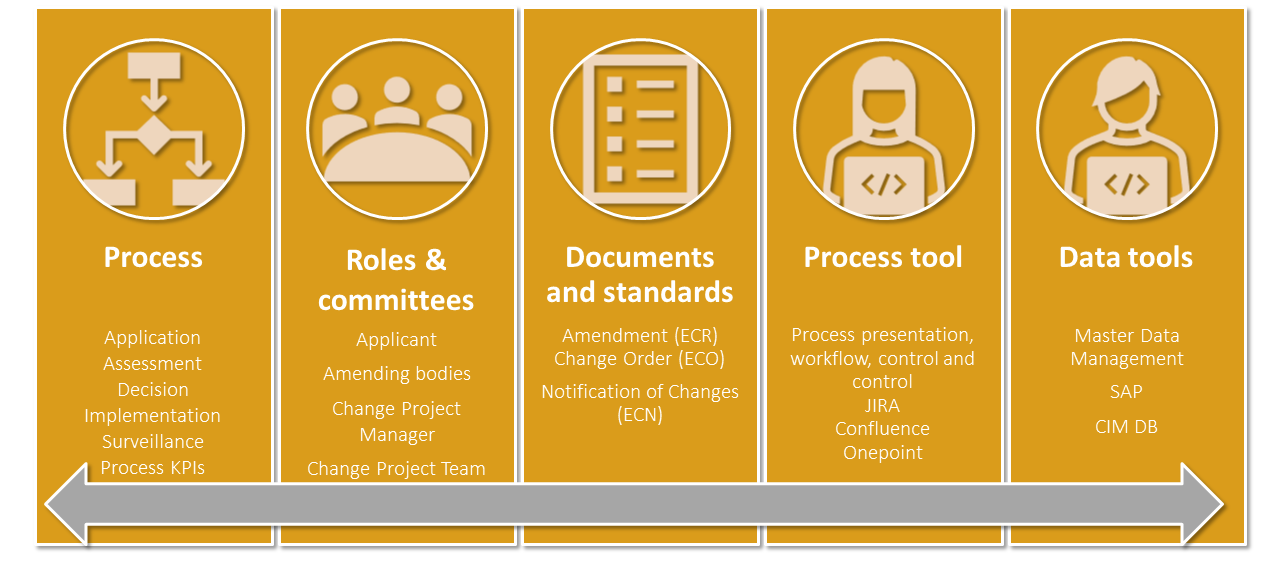

Once the concrete need for change has been identified, the next step is to process it accordingly. Five essential elements need to be developed:

- Process workflow

- Roles and committees

- Documents and standards

- Process tools

- Data tools

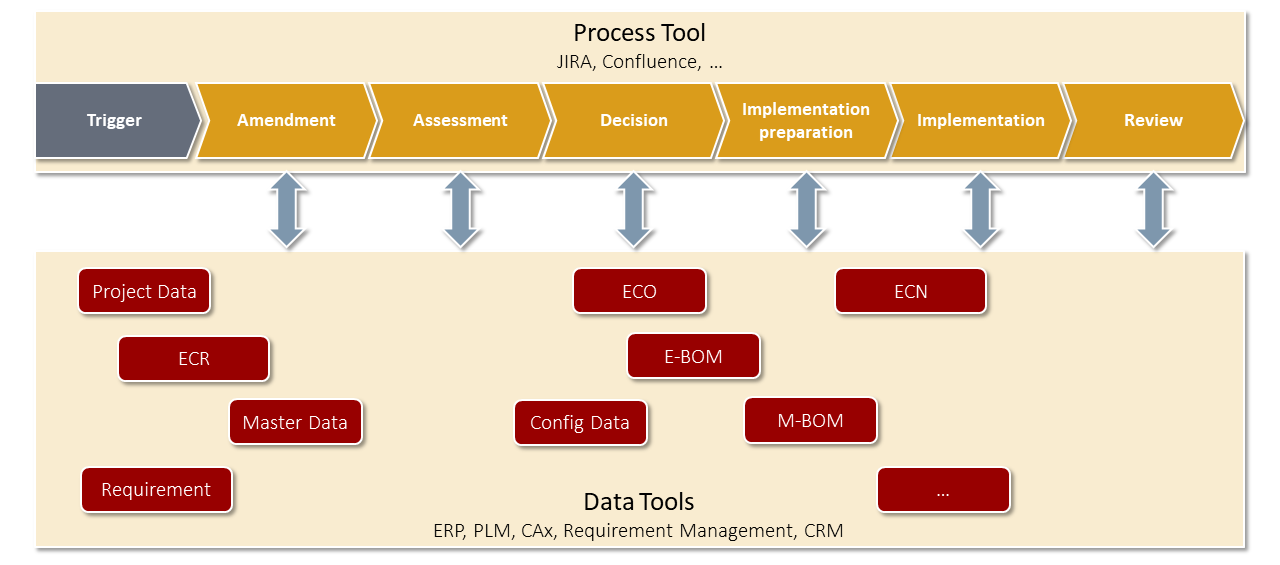

All elements are closely interrelated. The process starts with the formulation of the change request and the expected benefits of the change in a defined Engineering Change Request (ECR). Here, special attention must be paid to the identification of all components affected by the change and, in the case of multiple use of components, all affected end products and their phase in the product life cycle. The described scope of change then goes into the evaluation. It is important to involve all areas affected by the change in this step. Since this is often not obvious at the beginning of the assessment, it is a good idea to define a change committee that includes all potentially affected departments. In a concrete product development project, this could be the cross-functional core team, for example. The final decision must also be made within the cross-functional framework. Once the change has been positively decided, it is implemented in the affected areas by means of a change order or ECO (Engineering Change Order). The process should include an implementation and effectiveness check. After successful implementation, all relevant areas are released and informed by means of a change notice or ECN (Engineering Change Note).

Clear responsibilities are imperative throughout the process. For example, it must be clear who will steer the change request through the process. It must be ensured that all involved areas are involved, give their assessment and participate in the decision. It must also be defined who will drive the interdisciplinary implementation across departmental boundaries after a successful decision has been made. Particularly when it comes to bringing about the decision or controlling the implementation, it is useful to define clear criteria such as the greatest benefit from the change or the greatest share in the change in order to reliably arrive at clear responsibilities.

After a change has been implemented or rejected, documentation is of great importance. In the case of new change requests, it is important to be able to see whether a similar idea or requirement has already existed. Evaluations of the change history of a project or product are also important decision indicators, for example to ensure profitability. The use of tools and databases up to product data management solutions is not only important for documentation and journalisation. The definition of access rules and direct access to the parts, documents and models to be changed are among the advantages that the interaction between PLM system and a powerful product data management (PDM) solution can offer the user. In addition to data tools, process tools that map the change process and support process control also play an important role.

Our consultants know engineering change management from their industry and consulting experience. We are happy to complement our technical and change expertise in these projects with our know-how of suitable IT tools. We look forward to your enquiry and to working together to find the best solution for your challenge.

Your benefit

- They ensure that all change requests are fed into an orderly process.

- They ensure that decisions on change requests are made cross-functionally and on the basis of comprehensible criteria.

- You support the change process with high-performance process and data tools.

- They increase the speed, efficiency and transparency of engineering change management.

- They increase the profitability of their products.