Kanban

Kanban and Shop Floor Management put the flow back into R&D. Central elements of this agile method are: leading right where value is created, the "pull" principle, Kanban boards and a consistent work-in-progress (WIP) limit to prevent multitasking. This ensures more transparency, faster decisions, shorter lead times and fewer queues. We help you adapt Kanban to your requirements.

Bringing managers back to where the value is created

Todays’s R&D managers spend large portions of their time in meetings and on administrative tasks. They are supposed to manage R&D, but they lack the perspective to do so. As a result, the work of the teams suffers – workloads vary, priorities remain unclear, multitasking is common, decisions are delayed, waiting times ensue. The development organization virtually becomes "congested".

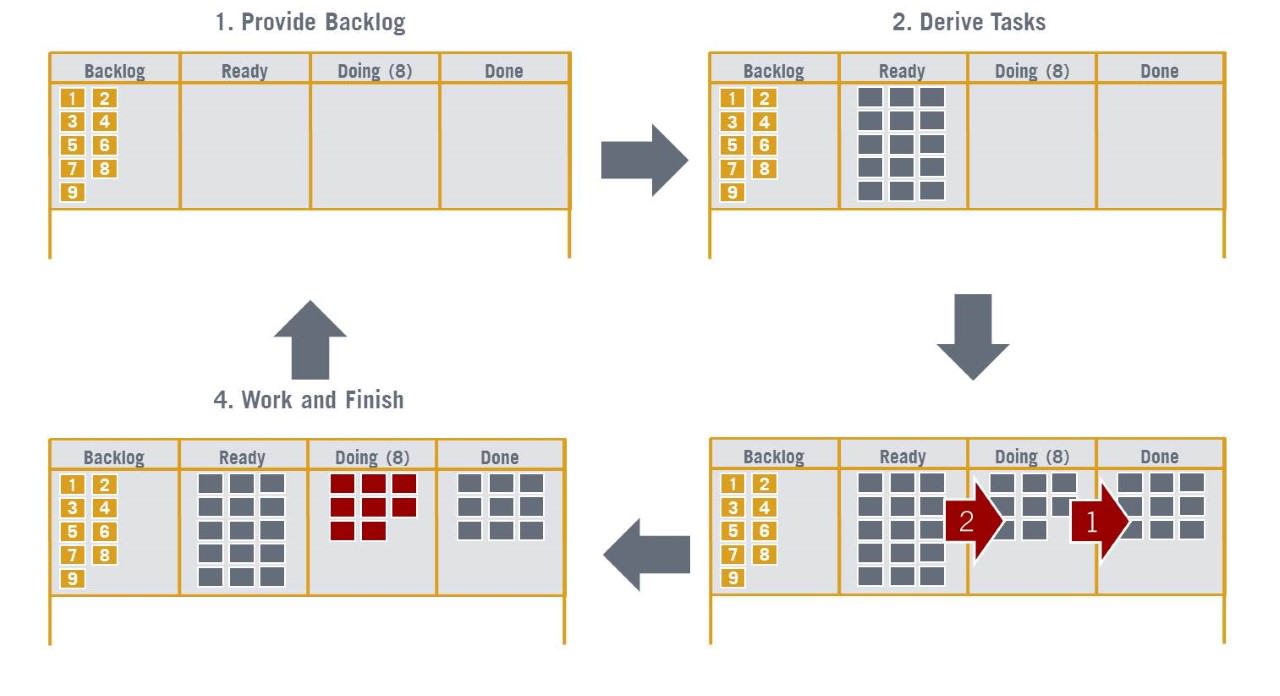

Kanban, in combination with Shop Floor Management, resolves this bottleneck. One key aspect: Kanban boards and daily stand-up meetings, which show the teams’ current work and problem areas, supported by indicators, progress overviews and boards for continuous improvement processes. This provides a holistic view. Increased transparency and faster decisions benefit everyone involved – both managers and R&D teams.

Other key principles are strictly limiting work in progress, forcing the completion of tasks once work on them has been begun and the "pull" principle. This prevents harmful multitasking and eliminates mental set-up times. The result is significantly improved efficiency and throughput times.

Kanban is well suited for managing tasks in the line organization of a multi-project management environment. The conventional project management organization remains in place. Daily project tasks, as well as product maintenance and other tasks in the line organization are managed using Kanban boards. No adjustments to the product development process or the project management system are necessary.

How Kanban Shop Floor Management gets your R&D flowing.

- In a multi-project environment, the agile method Kanban is suited to manage tasks in the line organization.

- A clear task prioritization ensures that employees always know what they should currently work on; the pull principle prevents congestion.

- Kanban boards provide a high level of transparency for everyone.

- WIP limits reduce the level of harmful multitasking and mental set-up times.

- In daily stand-up meetings, managers again manage their teams right where value is created.